EXACT to launch its new E-120, a compact extruder that will meet demands for edge trim recovery at high speed

EXACT to launch its new E-120, a compact extruder that will meet demands for edge trim recovery at high speed

Final tests and last touchups are underway at EXACT, a company based in Bergamo, Italy, that specializes in the construction of machinery for the recovery of plastic film trimmings. EXACT has chosen 2019 K-Show as a stage for the presentation of its latest model of extruder: EXACT E-120.

This new extruder is a compact unit that will meet demands for the recovery of very thick edge trim being run at high speeds. E-120 is suitable for the recovery of films containing mixtures of LDPE, LLDPE, mLLDPE, HDPE, EVA and barrier films containing coPA, and EVOH.

Moreover, EXACT also said that different film mixtures were also tested in the first test stage and gave positive results, thus leaving room for possible expansion of the range of materials that can be recovered with this new extruder model.

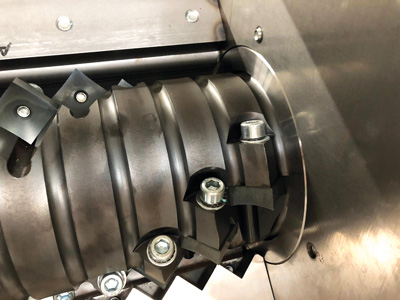

There are no official photos yet, since E-120 is making its debut at K in Düsseldorf from 16 to 23 October 2019. However, Nicolò Pepe, the Chief of R&D and General Manager of EXACT, has revealed a sneak preview of E-120’s first technical features.

There are no official photos yet, since E-120 is making its debut at K in Düsseldorf from 16 to 23 October 2019. However, Nicolò Pepe, the Chief of R&D and General Manager of EXACT, has revealed a sneak preview of E-120’s first technical features.

“Our new machine is capable of guaranteeing a production rate of 120kg regranulate/h and work in perfect harmony with high-speed systems. CAST lines with line speeds from 300 metre/minute or more, are in fact the field of choice for this new extruder model. The previous E-60 could not work in plants under such conditions. The presence of a shredder featuring 14 shredding blades placed above the mouth of the extruder, also allows it to work without difficulty also with films of considerable thicknesses.”

A new machine for the recovery of trimmings both In Line in a Closed Loop, Off Line as waste reels, and simultaneously.

“The addition of these components”, continues Pepe “as well as the extraction and entrance of the trimmings by air transport, became necessary because we tried to respond to a concrete market demand which, in our opinion, is in the growth phase of this particular production area. The introduction of E-120 alongside our Cold Recovery Systems – without fusion of the trim – which are particularly suitable for all those films that cannot bear a second fusion, such as BIO plastics, allows us to cover almost the entire market spectrum for edge trim recovery.”

Versatility and power

“Versatility and power are the two key concepts that have guided us in the development of this extruder” says Jacopo Pepe, (Executive Manager of EXACT together with his brother Nicolò). “That is the reason why it was also equipped with instruments that allow complete customization of its fundamental parameters allowing for better adaptation to various materials to be treated”.

E-120 features 5 independent thermoregulation zones, double pressure probe for a continuous control of the melt fluidity, head-unit filter change and extrusion die with 4 blades for air cutting. Independent adjustments can also be made on the cutting speed, towing and screw turns.

The operator can set all these different parameters through an intuitive interface, visible on a 10-inch Omron touchscreen connected to the extruder via a practical extendable arm, as to guarantee the operator the highest ergonomics.

“This year, EXACT celebrates its 45th anniversary and its CEO Noris Mazzoleni commented “even though we were born producing our now iconic Cold Recovery System machines, the development of our Hot Technology System has always given us great satisfaction. With the new EXACT E-120 extruder, we aim to expand the range of functionality of our extruders as to meet the real demands of many of our customers as well as of the plastic industry in its whole, hoping to launch EXACT toward a future that will hopefully be as favourable as it has been from 1974 to date.”

– which are particularly suitable for all those films that cannot bear a second fusion, such as BIO plastics, allows us to cover almost the entire market spectrum for edge trim recovery.”

Versatility and power

“Versatility and power are the two key concepts that have guided us in the development of this extruder” says Jacopo Pepe, (Executive Manager of EXACT together with his brother Nicolò). “That is the reason why it was also equipped with instruments that allow complete customization of its fundamental parameters allowing for better adaptation to various materials to be treated”.

E-120 features 5 independent thermoregulation zones, double pressure probe for a continuous control of the melt fluidity, head-unit filter change and extrusion die with 4 blades for air cutting. Independent adjustments can also be made on the cutting speed, towing and screw turns.

The operator can set all these different parameters through an intuitive interface, visible on a 10-inch Omron touchscreen connected to the extruder via a practical extendable arm, as to guarantee the operator the highest ergonomics.

“This year, EXACT celebrates its 45th anniversary and its CEO Noris Mazzoleni commented “even though we were born producing our now iconic Cold Recovery System machines, the development of our Hot Technology System has always given us great satisfaction. With the new EXACT E-120 extruder, we aim to expand the range of functionality of our extruders as to meet the real demands of many of our customers as well as of the plastic industry in its whole, hoping to launch EXACT toward a future that will hopefully be as favourable as it has been from 1974 to date.”