Magic MP has astonished once again with its fully electric accumulation machine that offers utmost precision and low consumption

Magic MP has astonished once again with its fully electric accumulation machine that offers utmost precision and low consumption

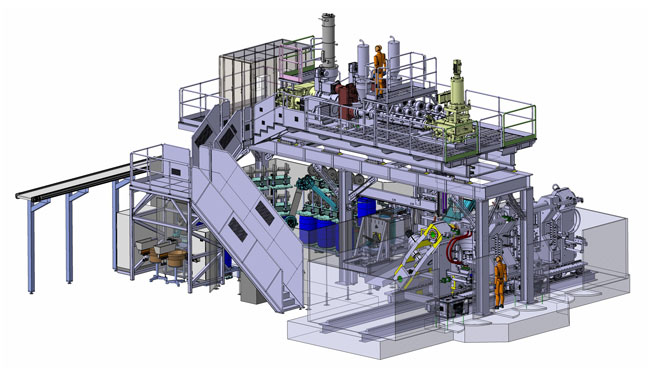

Magic has presented during the Open House in November the revolutionary fully electric accumulating machine with patented head and clamping.

Even the field of industrial machines have been revolutionized, the innovative ideas of Magic will give its clients enormous benefits in terms of profit and process.

Principal benefits:

- Reduction of consumption equal to -53%,

- Maximum precision of the movements. Consequent efficiency equal to 99% with a perfect repeatability of the working cycles, potential reduction of the working cycle and potential reduction of the weight of the articles to be produced,

- Reduction of the maintenance costs equal to -52%,

- Machine completely oil free,

- Very silent machine since it is free of hydraulic pumps.

Magic MP S.p.A. is an Italian company founded in 1959, specialized in the conception and construction of extrusion blow moulding machines (EBM) and injection, stretch e blow moulding machines (ISBM) of plastic materials.

Thanks to its constant orientation to innovation MAGIC has become an excellence of the Made in Italy and a worldwide reference point for all the operators of this field.

MAGIC has been the first company in the world to conceive fully electric machines, revolutionizing the field of plastic and tracing a new technological greener and more sustainable road.

The clients recognize in the MAGIC machines patented technological benefits, which turn into real process improvements and consequent profit increases. Investments and efforts to give to their actual and future clients a unique and solid contact point in the production of bottles: machines, moulds and packaging solutions. Everything is internally developped and produced and commercialized with the best value for money on the market.

These investments confirm the continuity of principles, values and skills that has been distinguishing Magic Group for more than 60 years.

With his words reported below the President of the Magic Group, Mr. Ferruccio Giacobbe, devotes the moon’s landing of his company on the planet of industrial machines and he does it always in an innovative and futuristic way.

“Innovation is and always will be the engine that fuel growth and development of Magic. Up to date no one in the world has ever built a completely electrified accumulator head of big size, Magic, which always looks ahead and, driven by this philosophy, has understood that even in the field of industrial machines the complete electrification will become a determining and indispensable factor. We did it in the past with the continuous extrusion technology for machine up to 60 Tons for the production, per example, in 6+6 cavities for 5 litres containers; we do it today also with the industrial machines for containers up to 280 litres. Soon we will do in fact a second Open Day to show the world the new transfer machine with all electric technology of 80-100 Tons for containers up to 280 litres. This machine will have an incredible saving for our clients in terms of energy consumption equal to almost 180.000 Euro per year. We are led to think that electrification is all about the necessity of the energetic economy. But this is one of the aspects, even though very important. The electric motor means also more precision and repeatability in the execution of the movements, that impacts on the efficiency of the machine, in lighter articles and shortest working cycles and with less wastes. It will be easy for our clients to understand how advantageous and innovative is to produce with a machine which consume 50-60% less, that thanks to its stability allows shortest working cycles and allows to produce lighter articles and even more with reduced maintenance costs of 50%.”

We are sure that orientation to ’Green”, to be effectively implemented, must bring to our clients even advantages in terms of profit. In fact, in 25 years and 1800 electric machines sold as well as having “saved” almost 3 billions of Kg in CO2, our clients have saved more than 500 million euro in electric energy. To these many various millions must be added for the economy in maintenance costs.

We want our clients, with our patented technology, win the complex challenge of the market; we aspire to become their partner, grow with them and become their reference point in the field.”