GIMAT guarantees maximum optimization, more complete control of the entire production cycle and prompt after-sales service

GIMAT guarantees maximum optimization, more complete control of the entire production cycle and prompt after-sales service

GIMAT Srl designs and produces systems for mixing, moving, dispensing and packing raw materials in the form of powders and granules for the food processing industry. The systems built comply with the customer’s specific requirements and all the applicable product directives.

The integrated system is assembled preferably with machinery designed and produced by us to be able to guarantee the user the maximum optimization, a more complete control of the entire production cycle and prompt after-sales service.

Examples of applications and integrations:

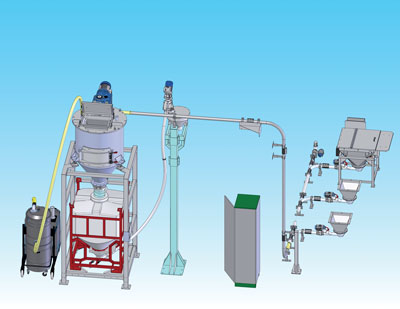

Photo 1

System for gluten-free cereal production, such as rice, corn and more, consisting of: Weight-control unloading by pneumatic conveyor from various bulk bag carrying stations, in-line cereal safety sieving, preparation, dosing and brine transfer, vertical rod mixing and cereal liquid absorption, residue-free unloading, storage and conveying to automatic process machines by means of a series of flexible hoppers.

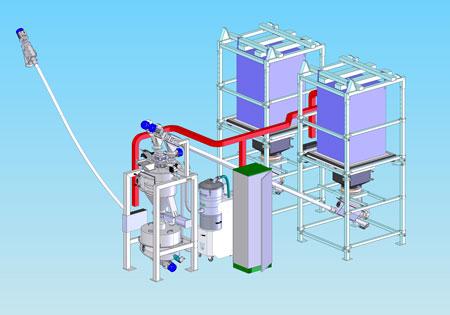

Photo 2

System for the ground coffee sector consisting of: Drawing from 2 bulk bag emptying stations and from a bag-emptying hopper by means of flexible screws and pneumatic delivery by suction. Vacuum produced directly inside the blender, which functions as a cyclone mixer thanks to its special geometrical design. The accumulation buffer under the mixer ensures infeed to the capping machine without deterioration of the blend and aroma.