Moretto, leading supplier of automation and auxiliary equipment for the plastic industry, listens to customer needs and responds effectively with dedicated and customized products

Moretto, leading supplier of automation and auxiliary equipment for the plastic industry, listens to customer needs and responds effectively with dedicated and customized products

Moretto S.p.A., leading supplier of automation and auxiliary equipment for the plastic industry, presents itself at K 2019 as a “partner of solutions”, capable of listening to customer needs and responding effectively with dedicated and customized products.

Starting from the customer and his specific needs, Moretto provides K 2019 visitors with an overview of unique solutions and systems, consisting of energy-saving technologies and 4.0 control and management devices, essential tools for an efficient and sustainable production.

At K 2019 Moretto presents the X COMB series of dehumidifiers, extended in the range to cover higher production needs. These mini dryers are a real combination of patented Moretto technologies: fully electric (they do not use compressed air), they are equipped with powerful turbo-compressors, zeolite technology, the Dew Point equalizer and the exclusive OTX hopper.

Particularly indicated for the drying of highly hygroscopic technical materials used in demanding sectors such as the medical, optical and automotive sectors, the X COMB dryers are the best allies in terms of efficiency and energy savings.

The ON series, with compact and robust models, is suitable for installation directly on the mouth of the processing machine, guaranteeing constant quality during the production process.

The SIDE series includes larger models up to 24 kg/h, with the installation next to the machine, to satisfy higher productions or in battery on trolley for maximum production flexibility.

Particular attention is paid to the drying of PET granules, a delicate phase especially for large productions, typical of the rigid packaging and beverage sectors.

In a dedicated area of the stand, Moretto presents a drying system consisting of a XD 800X series dryer combined with the OTX hopper and Moisture Meter Manager (MMM). A solution able to guarantee certifiable results, an absolute primacy in terms of energy efficiency for any type of material and a completely automatic system of the drying process.

The innovative turbo-compressors system of the XD 800X series dryer, together with the OTX hoppers, offer extraordinary levels of energy efficiency. Furthermore, the XD 800X dryers do not use either cooling water or compressed air, being this another advantage in the treatment of PET and ensuring energy saving compared to conventional dryers.

The use of the exclusive OTX hopper allows a homogeneous flow of the material inside the hopper during the process, guaranteeing an effective and controlled drying and an extraordinary energy efficiency of + 66%, also reducing the material treatment time. In the treatment of PET, one of the aspects to which Moretto customers are most “loyal” is the constant treatment of OTX which ensures a stable process and an improvement in machine cycle times, in the order of half a second. This is equivalent to producing up to 17 million additional preforms per year.

The application of MMM integrates the dryer into a “responsive” system as required by the 4.0 intelligent factory project. MMM measures the initial moisture of the granule and based on this, knowing the precise behaviour of each material, it performs the appropriate drying cycle to obtain the result requested by the customer in terms of final moisture, which is then monitored at the hoppers outlet.

In this way, MMM maximizes process performance and achieves incredible results in terms of energy savings.

At K 2019 Moretto proposes a series of solutions dedicated to “micro” conveying for the feeding and conveying of small quantities of technical materials. Very compact feeders, ideal for installation on stand-alone machines, on drying and dosing systems or directly on the throat of the processing machine. These conveying systems, like all of the Moretto range, include models specifically indicated for the use in clean rooms.

To automatically manage and supervise the entire conveying process of small or large quantities of plastic material, ONE WIRE 3 guarantees the greatest transport efficiency, thanks to its advanced FIFO logic.

ONE WIRE 3 also controls those devices, which with their exclusive technologies, contribute to optimizing the granule conveying and feeding process. In particular, the DOLPHIN manifold unit, automatically supplies and distributes all the materials to all the machines, avoiding any risk of contamination and human error.

KRUISEKONTROL, an exclusive Moretto patent, which the European Patent Office (EPO) recognized as “the only automatic and intelligent system in the world capable of defining the best transport conditions for each plastic material”. The uniqueness of this system lies in its ability to manage the speed of the material during the conveying phases, eliminating the peaks and the consequent formation of angel hair and wear of the pipes and adapt in a responsive way the transport conditions, differently from the various inverter systems that simply act on the air speed, but without taking into account the numerous variables that characterize each material (KK controls more than 15 parameters) and which constitute elements of strong differentiation in their behaviour in the pipe.

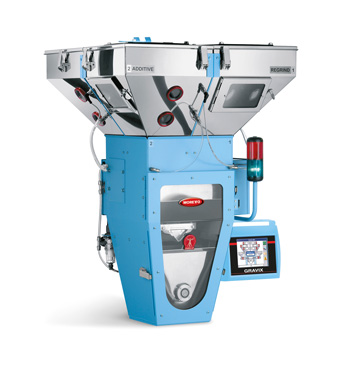

The DGM Gravix is the dosing unit that, thanks to its particular control with exclusive Vibration Immunity System and the double eyelid system, doses with precision up to 0.01% even when installed on a blow moulding machine, without being affected by the continuous movements and vibrations to which it is subjected.

The DGM Gravix dosing units cover dosing requirements for granule, powder and flakes materials, with dedicated applications, up to 12 materials and 12,000 kg/h. Applications dedicated to micro dosing, such as Rotopulse, make these machines extremely flexible in their use in the department.

DPK is a compact precise loss-in-weight dosing system, suitable for the dosing of small amounts of masterbatch or additives. The technology of the load cells and the control algorithm make DPK reaching dosing accuracy of up to ±0.03%. The masterbatch or additive to be dosed is contained in a hopper built in a specific transparent resistant acrylic material, free from electrostatic charges, which makes immediately visible the content material and the level of load and avoids the stop of material on the hopper walls. The hopper is easily removable without the use of tools and, together with the intelligent storage and recognition system of the masterbatches alongside the machine, the recipe change is even more immediate.

Moreover, Moretto offers a complete range of thermo and cooling systems to satisfy any production requirement, from single unit on the side of the machine, to ad hoc developed modular open centralized systems with a maniacal attention to total energy efficiency.